Extracting Pegging Information Page

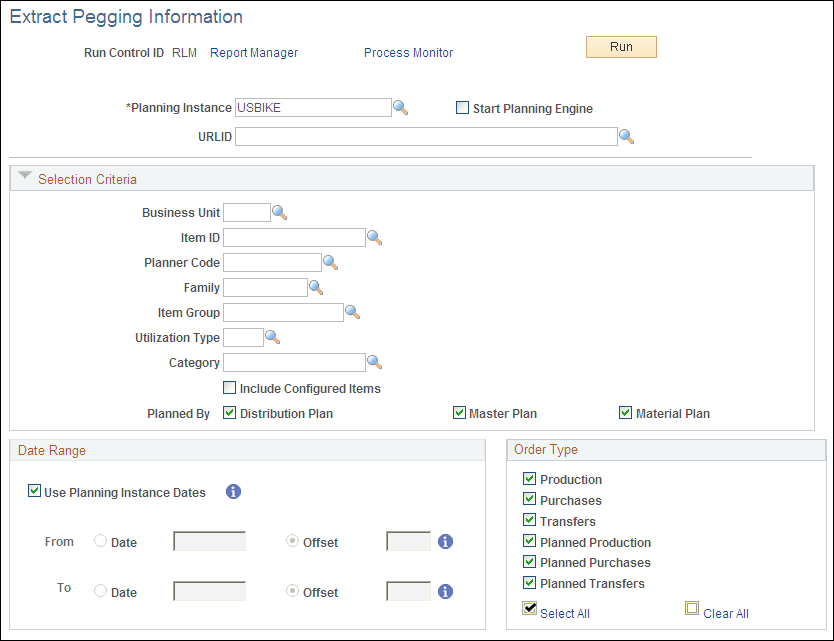

This process will extract information on supply that has been pegged to top level demand, and place it in the output table PS_SPL_PEGGING_INF. You will need to create a report to view the pegging information. You can filter the extracted output by adjusting the values within the Selection Criteria, Date Range, and Order Type group boxes.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

PL_PEGGING_REQ1 |

Extract information on supply that has been pegged to top level demand. |

Use the Extract Pegging Information page (PL_PEGGING_REQ1) to extract information on supply that has been pegged to top level demand.

Navigation:

Supply Planning, Solve Plan, Extract Pegging Information

This example illustrates the fields and controls on the Extract Pegging Information Page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Start Planning Engine |

Select this box and the process will start the planning engine prior to running the extract. |

Include Configured Items |

A non-active field that is related to a deprecated product. |

Offset |

Values entered in the Offset field will allow the date range to be based on a set amount of days earlier or later than the current date. |

Extract Pegging transaction calls several Show Demand methods. Pegging class are modified to be in sync with the Show Demand change. Similar to Show Demand, the pegging result also displays safety stock demand if any. The setting for safety stock option (Ignore, Ignore Until First Demand, or Fulfill) is obtained from Planning Instance’s safety stock option. The behavior is same as Show Demand.

To ensure planning instance’s safety stock option to pass on to pegging transaction, a new input parameter “IGNORE_SAFETY” is added to the PL_EXTRACT_PEGGING transaction.

This section explains the output from the Extract Pegging Information process. The values are stored in the PS_SPL_PEGGING_INF table. Listed below are some of the fields within the PS_SPL_PEGGING_INF table. Obvious and common fields are not noted.

PL_MRP_ORDER_TYPE (Planning MRP Order Type): The value in this field will be dependant on the source. These sources are:

020: Production Order

050: Planned Production Order

010: Purchase Order

040: Planned Purchase Order

030: Transfer Order

060: Planned Transfer Order

PL_DMD_ORDER_TYPE (Planning Demand Order Type): The value in this field identifies the top level demand type for the given supply. These demand types are:

020: Production Order Component

050: Planned Production Order Component

030: Transfer Demand

060: Planned Transfer Demand

120: Net Forecast

090: Sales Order

100: Buy Agreements

070: Stock Request

110: Extra Demand

300: Negative Quantity on Hand

600: No Demand

PL_ORDER_KEY (Planning Order Key): The value in this field is the order identifier of the top level demand for the given supply. These order identifiers are:

PRODUCTION_ID: Production Order Component

PL_SEQ_NBR: Planned Production Order Component

ORDER_NO: Transfer Demand

PL_SEQ_NBR: Planned Transfer Demand

PL_FORECAST_ID: Net Forecast

BUSINESS_UNIT/ORDER_NO: Sales Order

CNTRCT_ID: Buy Agreements

ORDER_NO: Stock Request

PL_SEQ_NBR: Extra Demand

PL_LINE_KEY (Planning Line Key): The value in this field is the line number of the top level demand for the given supply. These line numbers are:

OP_SEQUENCE: Production Order Component

OP_SEQUENCE: Planned Production Order Component

DEMAND_SOURCE/ORDER_INT_LINE_NO/SCHED_LINE_NO/DEMAND_LINE_NO: Transfer Demand

DEMAND_SOURCE/ORDER_INT_LINE_NO/SCHED_LINE_NO/DEMAND_LINE_NO: Planned Transfer Demand

DEMAND_SOURCE/ORDER_INT_LINE_NO/SCHED_LINE_NO/DEMAND_LINE_NO: Net Forecast

ORDER_INT_LINE_NO/SCHED_LINE_NBR/KIT_LINE_NBR: Sales Order

ORDER_INT_LINE_NO/SCHED_LINE_NBR/KIT_LINE_NBR: Buy Agreements

DEMAND_SOURCE/ORDER_INT_LINE_NO/SCHED_LINE_NO/DEMAND_LINE_NO: Stock Request

DEMAND_SOURCE/ORDER_INT_LINE_NO/SCHED_LINE_NO/DEMAND_LINE_NO: Extra Demand

PL_INV_ITEM_ID (Planning Inventory Item ID): The value in this field is the inventory item of the top level demand for the given supply. For Production Order Component and Planned Production Order Component, it is the value of COMPONENT_ID.

SETID: This field is for Buy Agreement only.