Making BOM Mass Changes and Creating Automatic Revisions

You can make BOM mass changes and create automatic revisions using MMCs.

To create automatic revisions using the mass maintenance by the Mass Maintenance Codes process:

Define the MMC using the BOM Mass Maintenance component.

Run the Mass Maintenance by MMC process.

The system creates a new revision effective on the Mass Maintenance by MMC process run date.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

Mass Maint Code Options |

EN_MASSMNT_REQ2 |

Define the MMC options for the BOM Mass Maintenance COBOL SQL process (ENPMMAIN). |

|

Assembly Item Options |

EN_MASSMNT_REQ3 |

Select the items to which the BOM Mass Maintenance process will be applied. |

|

Select Assemblies by Items Where Used |

EG_BOM_WHEREUSE_SP |

Quickly populate affected assemblies into the primary page. |

|

Select Assemblies by Items Where Used: Enter Dimensions |

EN_BOM_DIM_SP |

Specify the dimensions of the component. |

|

Select Assemblies by Items Where Used - Reference Designators |

EG_BOM_WU_REF_SP |

Specify the reference designator of the component. |

|

Mass Maint Except |

EN_MMC_TRN_STAT |

View the reasons that BOMs weren't changed by the BOM Mass Maintenance process. |

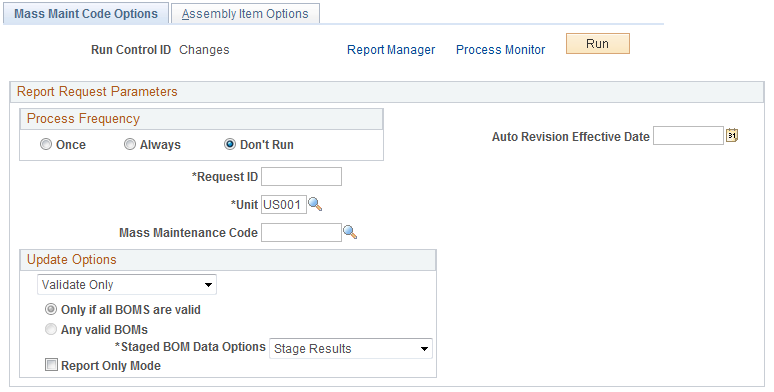

Use the Mass Maint Code Options page (EN_MASSMNT_REQ2) to define the MMC options for the BOM Mass Maintenance COBOL SQL process (ENPMMAIN).

Navigation:

This example illustrates the fields and controls on the Mass Maint Code Options page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Unit and Mass Maintenance Code |

Enter values to apply to a range or list of assemblies. If the MMC has been set to include automatic revisions, then the system automatically creates revisions. Revisions are effective as of the run date of this process or the date that you enter in the Auto Revision Effective Date field. Note: Only items that have been defined as revision-controlled with automatic revisions and also set up to use auto revisions (with the BOM Mass Maintenance - Search page) will be auto-revision incremented. |

Auto Revision Effective Date |

Enter the effective date to be used by all new auto-revisions that are created in this process run. If this field is left blank, then today's date is used as the new revision effective date. Keep in mind that all revisions within one process run will use the same date. If the date entered in this field provides a date that is earlier than an existing revision, then the revision will be given an obsolete date. Obsolete dates are based on the effectivity of the next revision. However, the most effective way to tie component obsolescence and new component effectivity to auto-revisions is to take advantage of the Schedule Date or Prior Date options offered on the Change page or the Add page of the BOM Mass Maintenance Codes component. This will eliminate possible errors caused by user-entered dates that do not correspond with the effective date selected for the new revisions. |

Update Options |

Select an update option. Values are:

Note: When running Mass Maintenance by ECO to create new revisions only, you must run the process using the Validate and Update value to create new revision numbers. |

Staged BOM Data Option |

Select an option to determine what should be done with the data that was used during the Mass Maintenance process:

|

Report Only Mode |

Select to view the results of the Mass Maintenance process by using the Mass Maintenance Staged BOMs component. If you don't select Report Only Mode, you can use the Mass Maintenance Staged BOMs component to view the staged BOMs, update errors and submit corrected BOMs for reprocessing. |

Use the Assembly Item Options page (EN_MASSMNT_REQ3) to select the items to which the BOM Mass Maintenance process will be applied.

Navigation:

Field or Control |

Description |

|---|---|

Item Options |

Select an item option. Values are:

|

|

Click the Search button to search for items to add to the list of assembly items. |

Run |

Click to run this request. PeopleSoft Process Scheduler runs the BOM Mass Maintenance COBOL SQL process at user-defined intervals. |

See the product documentation for PeopleTools: Process Scheduler

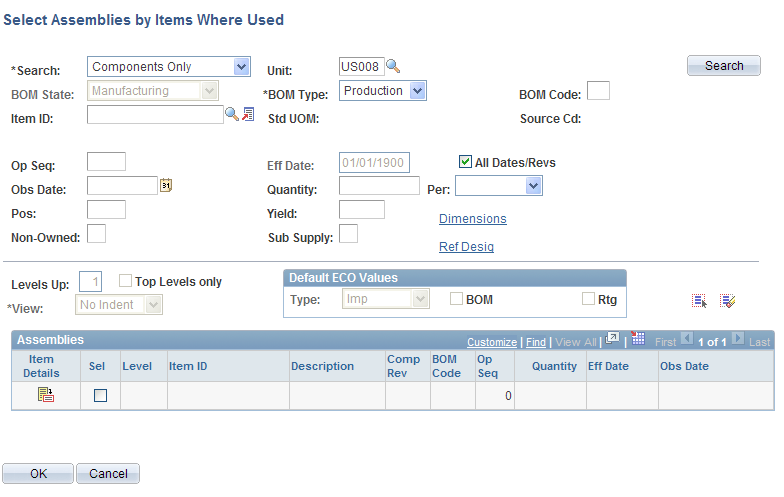

Use the Select Assemblies by Items Where Used page (EG_BOM_WHEREUSE_SP) to quickly populate affected assemblies into the primary page.

Navigation:

Click the Where Used link.

This example illustrates the fields and controls on the Select Assemblies by Items Where Used page. You can find definitions for the fields and controls later on this page.

This page enables you to quickly populate affected assemblies into the primary page.

Field or Control |

Description |

|---|---|

Search |

Values are:

|

Sel (select) |

Select the check box for all the outputs that you would like to transfer to the main page. |

Item ID, Op Seq (operation sequence), and BOM Code |

Enter values for these fields. |

Search |

Click this button to populate the page. |

View |

Select either Indented or No-Indent. |

Sel (select) |

Select this check box for all the components that you would like to transfer to the main page. |

Comp Rev (component revision) |

This field appears if the component is revision controlled. If you enter a component revision, the Select Assemblies by Items Where Used page returns all assemblies where that component is an exact match or where the current revision is used. If you leave the field blank, the system returns assemblies that use any revision of the component. |

Validation Checks

All requested changes made with the Process BOM Mass Maintenance by MMC page are validated before any MBOM changes are made. The system checks the interaction of all components and outputs on the product structure: these same checks are made within the BOM maintenance pages.

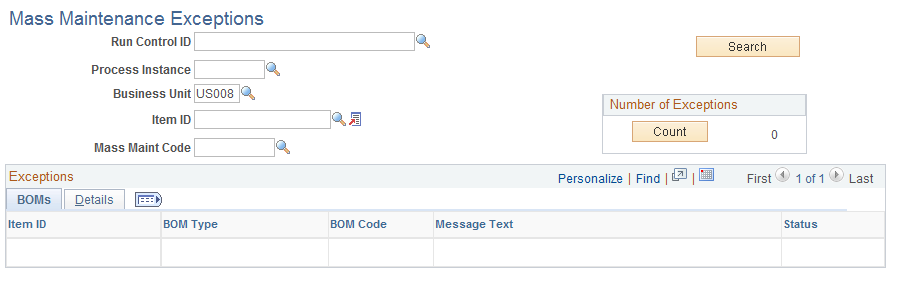

Use the Mass Maint Except page (EN_MMC_TRN_STAT) to view the reasons that BOMs weren't changed by the BOM Mass Maintenance process.

Navigation:

“

This example illustrates the fields and controls on the Mass Maintenance Exceptions - Mass Maintenance Except page. You can find definitions for the fields and controls later on this page.

Use this page to review the mass maintenance exceptions.

Click the Count button to view the number of exceptions.

After you've reviewed the exceptions and made any needed changes to the BOMs or mass maintenance data, you can then re-run the Mass Maintenance process.