Generating Production ID Splits

When required, you can split a single production ID into two or more production orders.

You can only split production with a status of In Process. Quantities can be split by operation based on the quantity that still exists at the original production ID operation sequence. You can also split a batch production ID order that has at least one co-product or by-product in addition to the primary item. You can split the entire production quantity to a new production ID, item ID or production area. All new production IDs will also have a production status of In Process.

You can only split production IDs. You cannot split production schedules.

Note: You cannot split an In Process production ID if there are pending pick plans, pending bar code transactions, or subcontracted operations that are also in process.

If you want to split a Pending Complete production ID, change the production status to In Process. You must reopen production to change the status back to In Process.

If you split a production ID that is being traced using serial genealogy, be aware of these issues:

You select the assembly serial IDs to split.

These serial IDs become disassociated from the original production ID and become associated with the new production ID. Any components associated with split assembly serial IDs are automatically transferred to the new production ID.

If the new (To) item is not using serial genealogy, you will no longer be able to track genealogy information.

In this scenario, the new production ID will not have any historical genealogy information.

You can use the associate serial commands to associate additional serial numbers with the new production ID.

You cannot transfer components to another production ID if they have been previously associated with a production ID using serial genealogy, unless those components are associated to an assembly serial that is being split.

In that case, they are automatically transferred. You cannot make serial associations when transferring components during the production ID split process.

This section lists common elements and discusses how to Generate Production ID Splits

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

SF_SPLITID_HDR |

Define production ID split information. Split only production IDs with a status of In Process. |

|

|

SF_SPLITID_OP |

Indicate the production quantity to be split from the original production ID at specific operation steps. Quantities can be split by operation based on the quantity that exists at the original production ID operation sequence. |

|

|

SF_SPLITID_CMP_SEC |

Edit components to be transferred to the new production ID. |

|

|

Production ID Split - History Page |

SF_SPLITID_HIST |

View production ID split history. |

|

Production History Page |

SF_TRANSHIST |

View production transaction history. |

|

Production History Details Page |

SF_TXN_HIST_SP |

View transaction history details. |

|

SF_COMP_TRANSFER |

Correct errors after a production ID split. Use this page to transfer components between production IDs to cover shortages. |

|

|

Component Detail Page |

SF_COMPTR_COMP_SEC |

View component shortages for the From production ID or the To production ID. |

Field or Control |

Description |

|---|---|

Component ID |

Component that is in effect for the production ID at the time of the production split. The component may be a substitute item. |

Op Seq (operation sequence) |

Operation step in which the components are required. |

From Production ID |

Original (From) production ID. If the production ID has been split multiple times, there is a separate entry for each split. The asterisk (*) indicates the original production ID. |

To Production ID |

New (To) production ID number. A new number is created each time the original production ID is split. |

Split Qty (split quantity) |

Production quantity split to the new production ID. |

From Prdn Area and Description |

Location where the original production ID was being manufactured. |

To Prdn Area and Description |

Location where the new production ID is to be manufactured. |

From Date, From Time, To Date, and To Time |

Beginning and ending date for the production that you want to view. The date and time fields refer to the date and time when the completion transaction was recorded. |

Date Timestamp |

Date and time the production ID split transaction occurred. |

Inquiries |

Option that enables you to view specified production transaction information. Values are:

|

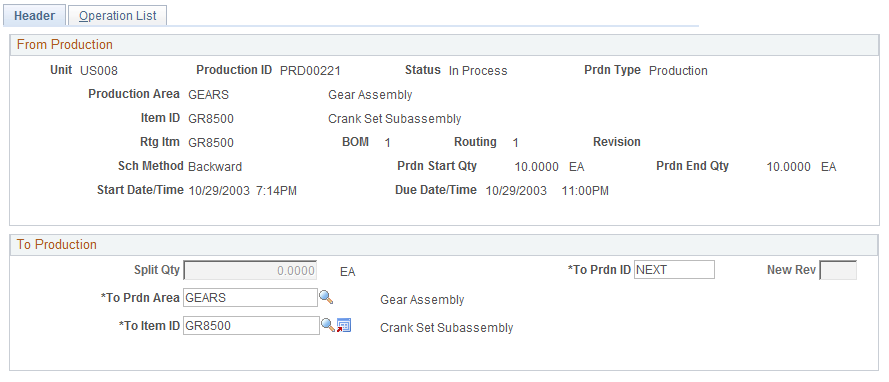

Use the Production ID Split - Header page (SF_SPLITID_HDR) to define production ID split information.

Split only production IDs with a status of In Process.

Navigation:

This example illustrates the fields and controls on the Production ID Split - Header page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

From Production |

Displays the production header data from the production ID that you are going to split. |

Split Qty (split quantity) |

If the production ID that you want to split has no operation list, enter the total quantity that you want to split from the original production ID. Whether you can enter a whole number or a decimal depends on the unit of measure and quantity precision combination that was defined for the item in PeopleSoft Inventory. For example, if item ID A0007 has a unit of measure of EA and a natural round, whole number combination, then you can only enter whole numbers. If you enter an incorrect number format, you'll receive an error message. If this field is unavailable, enter the split quantity on the Operation List page because there may be several operation steps with quantities that can be split. Note: You cannot split a higher quantity than what is remaining at the operation sequence. For example, suppose that there is a quantity of 20 at operation sequence 10. Then you cannot split more than 20. If you enter a higher split quantity than the quantity that is available, you receive an error message. |

View Trace Info |

Click to access the Traceability page, where you can view the assembly serial IDs that have been associated with this production ID. |

To Prdn ID (to production ID) |

Enter a value for the new production ID if you are not using automatic numbering. If you are using automatic numbering, retain NEXT as the value. |

New Rev (new revision) |

Enter a value if the item is revision-controlled and this new production ID represents a new revision for the end item. Note: Changes to the revision on the To item ID as reflected on the To production ID header only. Components copied during the production ID split process are based on the From production ID's component list and are not based on the revision number entered in the New Rev field. |

To Prdn Area (to production area) |

Select the area where the new production ID is processed. The production area for the To production ID can differ from the production area of the From production ID, but the end item must be assigned to the production area where you are moving the split quantities. If you select an area that has a WIP storage location that differs from the From production area, you receive a warning message indicating that any material issued in WIP is not automatically transferred to the new area's WIP location. Use the EZ Transfer page or the Material Release page to move the components to the new WIP location. |

To Item ID |

You can split the original production ID to the same item or to a different item. However, you cannot split a primary item to a batch item—that is, an item that has at least one co-product. If you're splitting a batch item to a different batch item, then the new item inherits the by-products from the original item ID as long as they are not fully completed on the from Production ID. In that case, they are not copied. Note: If the To item ID in a production ID split has an item status of Hold or Discontinue, you receive a warning message; however, the warning message does not prevent you from performing the action. These situations cannot exist when selecting a value:

|

Config Code (configuration code) |

Select or enter a value if the item is configured:

|

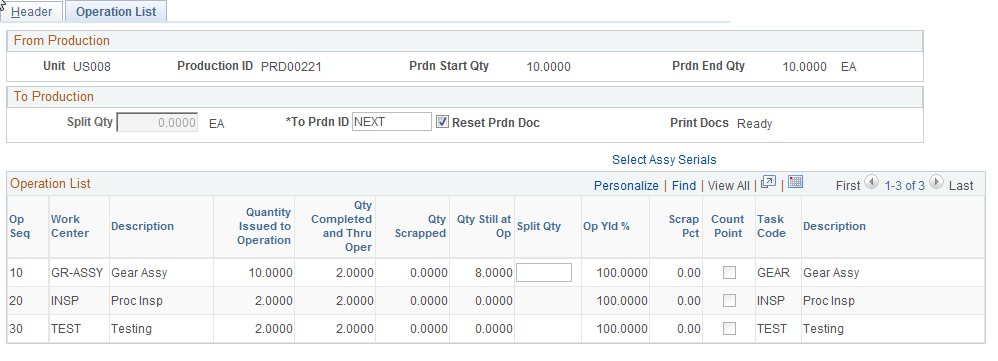

Use the Production ID Split - Operation List page (SF_SPLITID_OP) to indicate the production quantity to be split from the original production ID at specific operation steps.

Quantities can be split by operation based on the quantity that exists at the original production ID operation sequence.

Navigation:

Enter information on the Header page before accessing this page.

This example illustrates the fields and controls on the Production ID Split - Operation List page. You can find definitions for the fields and controls later on this page.

To Production

Field or Control |

Description |

|---|---|

Split Qty (split quantity) |

Appears only on the header of this page, when the From production ID has operations and reflects the total split quantity for the To production ID. |

To Prdn ID (to production ID) |

Use NEXT if you are using automatic numbering, or enter a specific production ID number for the new production ID. |

Reset Prdn Doc (reset production documents) |

Select to reprint the production documents for the To production ID. |

Components |

Click to view the production ID Components page. Use this page to make changes to the components that you're copying to the To production ID. This button is unavailable until a split quantity is entered at an operation. Note: If you are splitting the entire production quantity to a new production ID, you cannot make adjustments to the components. |

Operation List

This information appears for the From production ID, and is used to split operation data to the new production ID:

Field or Control |

Description |

|---|---|

Op Seq (operation sequence) |

Operation step in which processing has or will be take place. Components or ingredients can be added here. |

Work Center and Description |

Current location where the From production ID is processed. These fields are display-only and cannot be changed here. |

Quantity Issued to Operation |

Production quantity of assemblies completed at the prior operation and sent to the current operation. If the operation is the first operation in the process, the quantity issued to operation is the production ID quantity. |

Qty Completed and Thru |

Quantity completed at the operation. This quantity does not include any scrapped assemblies. These fields are display-only and cannot be changed here. |

Qty Scrapped (quantity scrapped) |

Number of assemblies that have been scrapped at the operation sequence. This field is display-only. |

Qty Still at Op (quantity still at operation) |

Production quantity that is considered still in process and that can be split to a new production ID. This display-only field is calculated using this formula: (Issued quantity) -

(Quantity completed and through the operation) + Scrapped quantity)

|

Split Qty (split quantity) |

Enter the production quantity to be transferred to a new production ID. Enter a split quantity for each operation that has a quantity remaining at the operation. However, you cannot split a quantity that is greater than the quantity still at the operation sequence. Note: You can split the entire original production quantity if you have not recorded any completions or scrap at any prior operations. |

Scrap Pct (scrap percentage) |

A weighted average of the scrap percentage specified when recording end item completions and scrap. This percentage represents the percentage of run time expended before the end item is scrapped. |

Count Point |

The check box is display-only if this operation sequence is a count point. Define an operation step as a count point on the new production ID by using the Operation List Maintenance page. |

Task Code and Description |

Task that is performed at the operation step. |

See the product documentation for PeopleTools: Process Scheduler

Use the PID Split Component List page (SF_SPLITID_CMP_SEC) to edit components to be transferred to the new production ID.

Navigation:

Enter a Split Qty (split quantity) on the Production ID Split - Operation List page. Click Tab and click the Components button.

Issue Quantities Tab

Field or Control |

Description |

|---|---|

Issue Qty (issue quantity) |

For components using the issue or replenishment material issue method, this is the quantity consumed from the WIP location for the component and is charged to WIP. For components using the kit method, this is the quantity issued directly to the production ID. |

Yield Loss Qty (yield loss quantity) |

Represents the number of components lost or damaged during the production run. |

To Issue Qty (to issue quantity) |

Represents the quantity of the component to be transferred to the new production ID. It's automatically calculated based on the end item quantity being transferred and the QPA of the component. This field is available if there are remaining assemblies that can be transferred at the operation sequence where the production ID split is occurring and components are tied to the operation sequence. Enter the quantity that you want to transfer to the To production ID. |

To Yield Loss Qty (to yield loss quantity) |

The quantity of components that was scrapped during the assembly process and consumed from the WIP location. This amount is transferred to the To production ID. This field is available if there are remaining assemblies that can be transferred at the operation sequence where the production ID split is occurring and the components are tied to the operation sequence. Enter the quantity that you want to transfer to the new (To) production ID. |

Iss Qty Total (issue quantity total) |

The total number of components to be issued to the To production ID. For lot- or serial-controlled items, this quantity represents the sum of lot or lot quantities that you specified on the Lot/Serial page, which you access by clicking the button on the first column of the row. This field is display-only and cannot be changed here. |

Pending Quantities tab

Field or Control |

Description |

|---|---|

Sched Qty (schedule quantity) |

Represents the quantity per assembly based on the quantity entered and production quantity. |

Pend Issue (pending issue) |

Displays the quantity used based on the quantity completed at the operation multiplied by the quantity per assembly. If the component's quantity is expressed per order, this is the quantity for each order. This quantity has not yet been consumed from the WIP location due to material shortages. |

Pend Loss (pending loss quantity) |

Represents the quantity of components scrapped during the assembly process but not yet consumed from the WIP location due to material shortages. This quantity is based on the From production ID. |

To Sched Qty (to scheduled quantity) |

Displays the total number of components scheduled to be used for the To production ID. |

To Pend Issue (to pending issue quantity) |

Represents the new (To) production ID quantity used based on the quantity completed at the operation multiplied by the quantity per assembly. If the component's quantity is expressed as per order, this is the quantity for each order. |

To Pend Loss (to pending loss quantity) |

Represents the quantity of components scrapped during the assembly process but not yet consumed from the WIP location due to material shortages. |

Original Component ID |

Displays the name of the original component ID. |

OK |

Click to return to the Operation List page. |

Save |

Click to process the production ID split. When you save the page, the production ID split is generated and these actions occur:

|

Note: If you are splitting the entire production quantity, all the material, actual labor and machine hours, earned conversion costs, actual conversion costs, and scrap costs are copied to the To production ID. The production status of the original production ID is set to Canceled, and it has a production quantity of 0.

Note: You can make manual changes to the To production ID by using the Production ID Maintenance, Component List Maintenance, or Operation List Maintenance pages. Make changes to the production start or production end quantity, BOM code, scheduling method, start date and time, or due date and time.

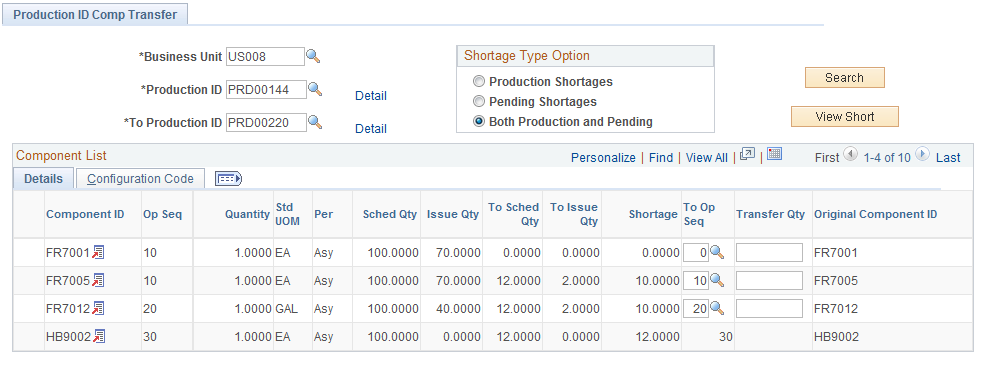

Use the Production ID Comp Transfer page (SF_COMP_TRANSFER) to correct errors after a production ID split.

Use this page to transfer components between production IDs to cover shortages.

Navigation:

This example illustrates the fields and controls on the Production ID Comp Transfer page. You can find definitions for the fields and controls later on this page.

Note: You can only perform component transfers on production orders with a status of In Process. In addition, only production ID materials that have actually been issued from the original production ID can be transferred to the To production ID.

Click the Detail link to view production details for either the From production ID or the To production ID.

Field or Control |

Description |

|---|---|

Shortage Type Option |

You can view all components on the From production ID or only the components that currently have shortages on the To production ID. If you view component shortages, the values are:

|

Search |

Click to retrieve the selected production ID information. |

View Short |

Click to view the components that have shortages. |

View All |

Click to retrieve all components. |

|

Click the Component Search button to access these links:

|

Component List

Field or Control |

Description |

|---|---|

Issue Qty (issue quantity) |

Number of components already issued or consumed on the From production ID. |

To Sched Qty (to schedule quantity) |

Scheduled or required component quantity on the To production ID based on production quantity and component's quantity per assembly or quantity per order. |

To Issue Qty |

Number of components already issued to the To production ID. |

To Op Seq (to operation sequence) |

Select the operation step in which the component is added to the To production ID. |

Transfer Qty (transfer quantity) |

Enter the quantity of the component that you want to transfer to the To production ID. If you enter a quantity that is less than the quantity that is outstanding, a pending issue quantity remains. |

Original Component ID |

Appears if the component was a substitution for another component requirement. |