Checking the EBOM Verification Status

This topic discusses how to check EBOM verification status.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

EN_BOM_VERIFY_REQ |

Check EBOMs for unwanted loops. |

|

|

EN_BOM_VERIF_DEL |

Delete records created by the EBOM Verification Request process (ENPBEXPV) by process instance. |

|

|

EN_BOM_VERIFY_STAT |

View, on a summary level, a list of all verified EBOMs or a list of all looping EBOMs discovered as a result of running the Verification Request page. |

|

|

EN_BOM_VERIFY_DET |

View a detailed list of all looping BOM components discovered as a result of running the BOM Verification Request page. |

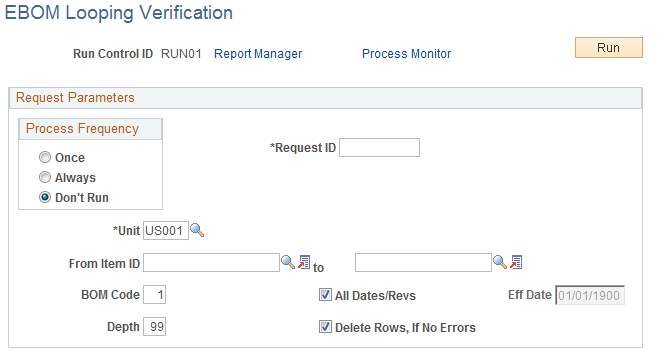

Use the EBOM Looping Verification page (EN_BOM_VERIFY_REQ) to check EBOMs for unwanted loops.

Navigation:

This example illustrates the fields and controls on the EBOM Looping Verification page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

BOM Code |

Enter the code for the BOM that you want to verify. |

Depth |

Determine how many levels to verify. |

Delete Rows, If No Errors |

Select to delete BOM explosion table records. The verification request process adds a series of records to the BOM Explosion table. These records take up space and are useless, if there are no looping BOMs. You can also use the Delete Verification Details page to save space. |

The EBOM verification COBOL SQL process (ENPBEXPV) checks for loops within EBOM structures only. Once you copy the EBOM to manufacturing, run the BOM verification within PeopleSoft Manufacturing to verify the BOM within manufacturing.

Instead of running this process, you can use Online BOM Verification to check for loops. You set the Online BOM Verification option at the manufacturing business unit level with the MFG Business Unit Options page. However, to improve BOM maintenance performance when BOMs are complex and deep, use the scheduled verification process and set Online BOM Verification to Never Verify Online.

EBOM Looping Verification looks at just the primary EBOM and routing, when exploding at levels greater than 1. If there is more than one way to make a specific co-product output, tell the system which EBOM is the primary way to make that co-product and, therefore, which EBOM to verify for that co-product. To tell the system which EBOM to verify, select an associated primary BOM on the Define Business Unit Item - Manufacturing: General page.

Note: Both MBOMs and EBOMs use the same associated primary; there isn't one specific to MBOMs.

Output Example

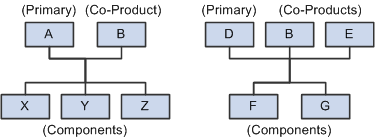

The following diagram illustrates how two different processes could have the same output. In this example, B is an output on two different processes:

BOM Output Example

Consider the two structures:

In the first structure, A is the primary (item), with B as the co-product, and X, Y, and Z are components.

In the second structure, D is the primary, and B and E are co-products, with F and G as the components.

Because there are two ways to make the same product (B), you need to decide which structure to use when exploding to lower levels. Therefore, you need to signify a primary structure associated with each item that may exist as a co-product, but not as a primary. To do this, assign an associated primary EBOM.

When exploding to lower levels, the system checks whether there is an associated primary defined for this item. If there is an associated primary item, the system uses it to explode to lower levels.

If exploding EBOM code 2 for the co-product, and an associated primary was defined, then the system uses EBOM code 2 for the associated primary, also.

For instance, if the system is exploding B (in the diagram) for EBOM code 2, and A is the associated primary, then the system looks for an item with an EBOM code 2 to explode. If EBOM code 2 doesn't exist for A, then the explosion stops for this item, and the system generates an error. This same logic is used for BOM verification, inquiries, and costing.

You receive a message only if the system finds a looping BOM. You can view the results of the verification process by using the BOM Verification Status page.

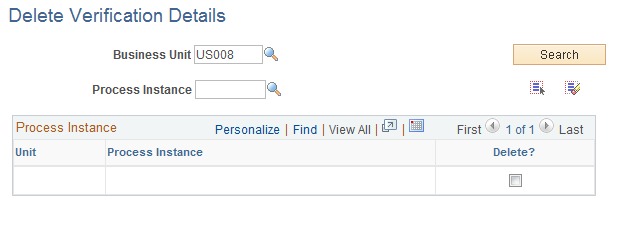

Use the Delete Verification Details page (EN_BOM_VERIF_DEL) to delete records created by the EBOM Verification Request process (ENPBEXPV) by process instance.

Navigation:

This example illustrates the fields and controls on the Delete Verification Details page. You can find definitions for the fields and controls later on this page.

The verification request process adds a series of records to the BOM Explosion table. These records take up space and are useless if there are no looping BOMs. You can use this page to delete these records by process instance.

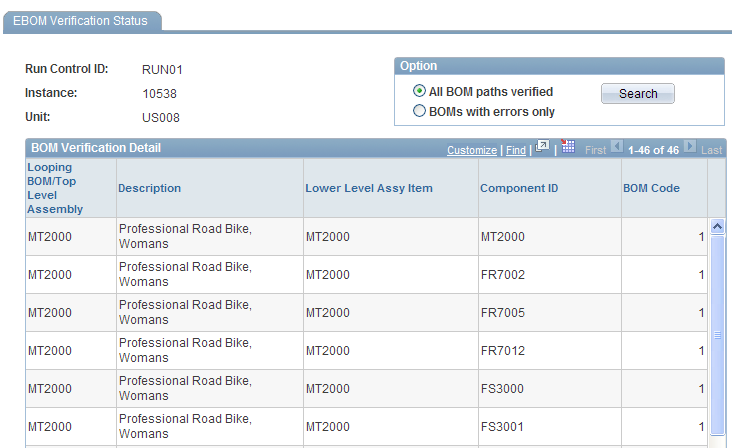

Use the EBOM Verification Status page (EN_BOM_VERIFY_STAT) to view, on a summary level, a list of all verified EBOMs or a list of all looping EBOMs discovered as a result of running the Verification Request page.

Navigation:

This example illustrates the fields and controls on the EBOM Verification Status page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

All BOM paths verified |

Select to enable the system to display all verified BOMs by top-level assembly. |

BOMs with errors only |

Select to enable the system to display all looping BOMs, along with the specific looping lower-level assembly and component items. |

Search |

Click to check for looping BOMs. If the system does not detect any loops, a message appears. If the system detects any looping BOMs, they appear at the bottom of this page. |

Details |

Click for any top-level assembly with errors to access the BOM Verification Detail page. |

Use the BOM Verification Detail page (EN_BOM_VERIFY_DET) to view a detailed list of all looping BOM components discovered as a result of running the BOM Verification Request page.

Navigation:

Click a Detail link.

Field or Control |

Description |

|---|---|

Lvl (level) |

Indicates the level where the loop in a BOM occurred. |

Component ID |

Indicates the specific component where the loop in a BOM occurred. |

BOM Code |

Indicates the BOM code for the BOM in which the loop occurred. |

Pos Nbr (position number), Op Seq, Eff Date, Obs Date, and Associated Primary BOM |

This additional information appears for the BOM in which the loop occurred. |